1/ 20

Description

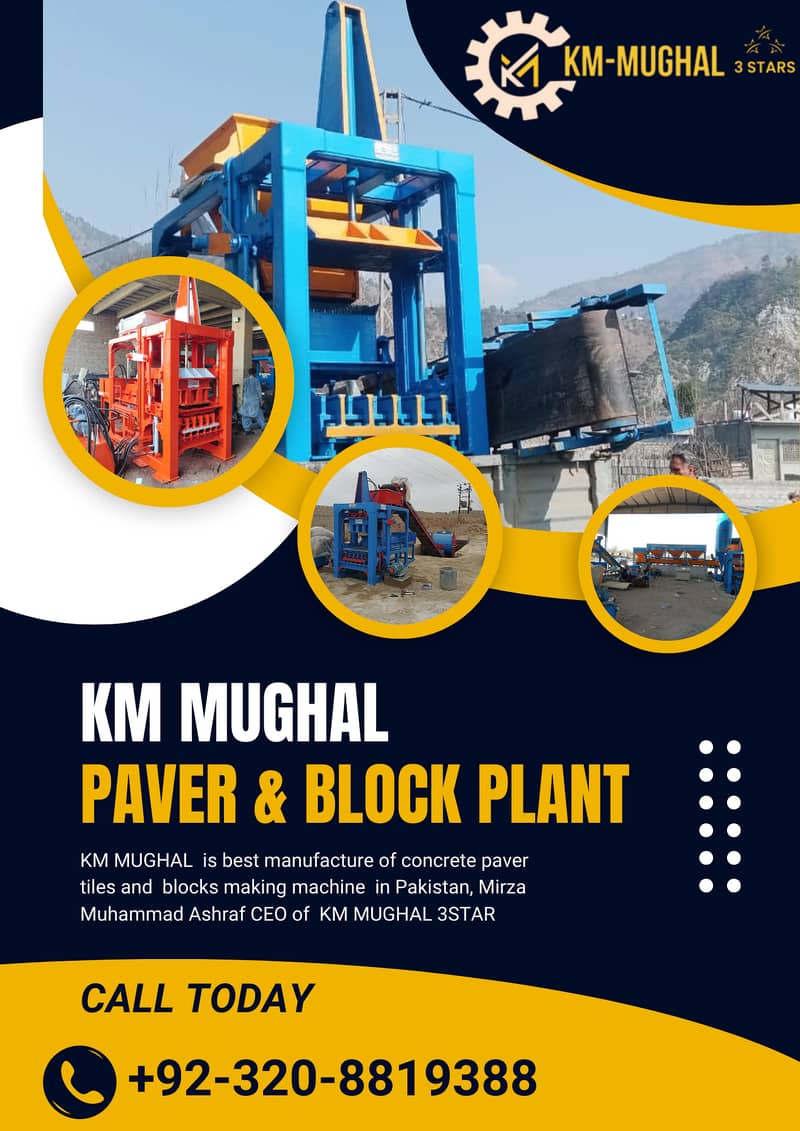

"KM MUGHAL 3 STAR Automatic Concrete Paver Tiles & Block Making Machine – High Output, Multipurpose, Energy Efficient!"

1. Introduction & Overview

KM MUGHAL 3 STAR Engineering Works, Pakistan’s premier manufacturer of advanced concrete machinery, proudly presents the Automatic Concrete Paver Tiles & Block Making Machine—designed for contractors, developers, housing societies, road-builders, and construction material suppliers seeking high-quality, high-output production of paver tiles, hollow blocks, solid blocks, and kerbstones. Engineered with robust components, user-friendly controls, and energy-efficient hydraulics, this versatile plant delivers superior precision, consistent quality, and rapid ROI.

2. Key Features & Highlights

Multifunctional Mould System: Quickly switch between moulds for paver tiles, hollow blocks, solid blocks, and kerbstones with minimal downtime.

Fully Automatic PLC Control: Intuitive touchscreen interface, programmable recipes, auto-cycle production, and real-time monitoring.

High-Performance Hydraulics: Optimized hydraulic circuits for maximum compaction force, ensuring dimensional accuracy and surface finish.

Vibration & Compression Combo: Dual-stage vibration followed by static pressure guarantees dense, durable products.

Energy Efficiency: Low-power motors and variable-frequency drives reduce electricity consumption by up to 30% compared to conventional systems.

Modular Construction: Expand or relocate the plant easily; add batching modules or conveyor systems as your production needs grow.

Robust Steel Frame: Heavy-duty construction, powder-coated finish, and corrosion-resistant components for longevity in harsh jobsite environments.

Rapid Cycle Times: Capable of producing up to 12,000 pieces per 8-hour shift (paver tiles) and 7,000 pieces per shift (blocks), depending on mould size and recipe.

Custom Mould Design: KM MUGHAL can fabricate bespoke moulds for any block, paver pattern, or kerbstone profile—in-house, in record time.

Comprehensive After-Sales Support: Installation, commissioning, operator training, spare parts inventory, and 12-month warranty on hydraulics and vibration systems.

3. Technical Specifications

Parameter

Specification

Model

KMSP-1500 (Standard)

Power Requirement

25 kW (3-Phase, 380V)

Hydraulic Pump Capacity

30 L/min @ 140 Bar

Compression Pressure

Up to 240 Bar

Vibration Frequency

0–6000 VPM (Variable)

Cycle Time

20–25 seconds (per mould)

Max. Production (Pavers)

12,000 pcs/shift

Max. Production (Blocks)

7,000 pcs/shift

Plant Dimensions (L×W×H)

4.5 m × 2.0 m × 2.2 m

Gross Weight

3,500 kg

Control System

Siemens PLC & HMI with Remote Access

Auxiliary Equipment

Hydraulic Power Pack, Vibrator, Conveyor Outfeed

4. Machine Workflow & Layout

Material Feeding: Aggregates and cement mortar pre-mixed and fed via conveyor/hopper.

Form Filling: Automatic feeder and shaker ensure uniform distribution in moulds.

Vibration & Compression: Programmable cycles optimize density and finish.

Demoulding: Hydraulic lifter ejects blocks/pavers onto outfeed conveyor.

Stacking & Curing: Units collected and stacked for accelerated steam or water curing.

5. Production Capacity & ROI

Example Case: A mid-sized contractor running a single-shift operation can recoup capital investment within 6–9 months, assuming market sale price of PKR 10–12 per paver tile and PKR 7–8 per hollow block.

Scalability: Add a second shift or parallel line to double output. Integrates with automated curing chambers for 24/7 operation.

6. Applications & End-Products

Interlocking Paver Tiles: Driveways, walkways, shopping malls, parks, industrial yards.

Hollow Blocks: Load-bearing walls, partition walls, boundary walls.

Solid Blocks: Foundation walls, security walls, sustainable building applications.

Kerbstones: Road edges, garden borders, urban landscaping.

7. Why Choose KM MUGHAL 3 STAR?

35+ Years of Expertise: Decades of proven performance in concrete machinery manufacturing.

Related ads

Your safety matters to us!

- Only meet in public / crowded places such as metro stations and malls.

- Never go alone to meet a buyer / seller, always take someone with you.

- Check and inspect the product properly before purchasing it.

- Never pay / transfer any money in advance before inspecting the product.

Ad ID: 1101048319