1 / 20

Details

Price65,000

Description

A solid block making plant is a facility that produces building blocks made from concrete or other materials. These blocks are used in the construction of buildings, walls, and other structures. The process of making solid blocks involves mixing cement, sand, and water, and then molding the mixture into the desired shape using a block making machine.

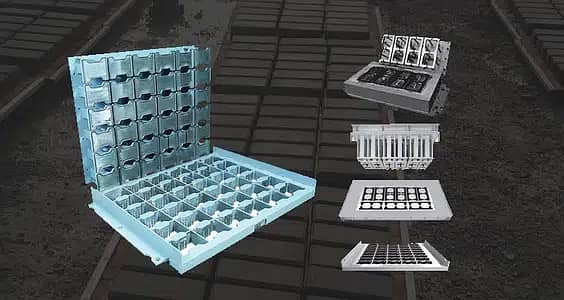

Elevate your construction projects with our state-of-the-art concrete blocks and tiles making plant by KM Mughal. Our automated plant is capable of producing lightweight fly ash bricks, CLC blocks, and paver tiles/tuff tiles with unparalleled precision and efficiency. With customizable molds and advanced control systems, you can tailor the production to meet your exact specifications. Invest in quality and reliability - contact us today for more information and to

To set up a solid block making plant, you will need to consider several factors, including the location, the size of the plant, the availability of raw materials, the cost of equipment and materials, and the market demand for building blocks in your area.

Here are some basic steps to consider when setting up a solid block making plant:

1. Conduct market research: Determine the demand for building blocks in your area and identify potential customers.

2. Select a suitable location: Choose a site that has easy access to raw materials, transportation, and utilities.

3. Purchase or lease equipment: You will need a block making machine, concrete mixer, molds, and other equipment.

4. Source raw materials: You will need to purchase cement, sand, and other materials from suppliers.

5. Hire staff: You will need to hire workers to operate the equipment and manage the plant.

6. Obtain necessary permits and licenses: You will need to obtain permits and licenses from local authorities to operate the plant.

7. Market your products: Develop a marketing plan to promote your building blocks to potential customers.

It is important to note that setting up a solid block making plant can be a capital-intensive venture, and it is important to conduct a feasibility study and develop a comprehensive business plan before investing in the project.

KM. MUGHAL’s fly ash bricks-making plant, as well as Blocks & tiles-making machines, have been immensely consistent and dependable passing through various international quality parameters. Our fly ash bricks producing Plants are manufactured under the supervision of technical expertise as per the global standard. We have created a vast demand for our precision-engineered products.

We provide a variety of concrete Blocks & Tiles Making plants and cement fly ash bricks that can be operated Manually, Semi-automatically, and Automatically. Concrete fly ash bricks, blocks & Tiles Making plants are equipped with batching system, mixing system, block machine, handling system including Electric Panels, Electric Valves, Hydraulic system, and can produce Edged-Stone, Curb-Stone, Standard bricks, Hollow Blocks, and solid blocks, fly ash bricks, cement bricks, concrete bricks, pavers (paving stones), revetments, retaining wall blocks and other construction and civil engineering materials.

Our Concrete block machines & fly ash bricks making machines are divided into three categories: The Manual operation plants Model KM-6 & KM-12 which are cost-effective for a small number of fly ash bricks and blocks & Tiles. The second is Semi-Automatic plant Model KM-15 fly ash bricks and Concrete Blocks & Tiles Making Machine which is widely used in Pakistan for medium quantity. However, Fully-automatic is Model KM-24, KM-28 & above. Which is highly used for a large number of fly ash bricks and Blocks & Tiles and designed with regard to the handling syste maximum block height.

“K. M MUGHAL 3 STAR ENGINEERING WORKS” Keeps the tent of making its customers get benefits at the maximum level for going forward hand-in-hand and striving for developments together.

The Silent features:

High Speed.

Corrosion Resistant.

Safe Operations.

Hydraulic Systems.

Highest PSI of Finished Product.

Low Maintenance.